news 2021

CRP Technology launches Windform® RS

May 26, 2021

CRP Technology makes available a new material from Windform® TOP-LINE range, the polyamide-based Carbon fiber filled composite Windform® RS for professional 3D printing with composite polymers fibers-reinforced, which delivers strength, stiffness and ductility required for heavy-duty applications.

This latest advancement from CRP Technology was created and formulated at the company’s Italian-based facility for use in additive manufacturing via Laser Polymer Melting technology.

Engineer Franco Cevolini, CEO and CTO, CRP Technology: “We’re building upon CRP Technology’s expertise in AM to create new composite materials at the highest level for our customers’ benefit. Our focus on innovation led to the creation of an ever-increasing diverse range of production-grade materials for Additive Manufacturing.”

“In the past three years” Engineer Cevolini adds “we have launched five new materials, two for the new-born family Windform® P-LINE for HSS technology, and three for the world-renowned Windform® TOP-LINE family for Laser Polymer Melting.

“CRP Technology has been always working hard to bring forward customizable PBF 3D printing solutions for any scenario; we have always anticipated the requirements of the market, and the most recent analysis support our vision: according to the latest surveys additive manufacturing adoption is increasing significantly as well as moving prototypes into production and scaling the manufacturing of production parts. Moreover, the use of 3D printing for production parts is expected to double over the next 3 to 5 years.”

Windform® RS has a very high Tensile Strength (85.25 MPa) and at the same time an excellent ductility (Elongation at Break of 9.46%) and a low density (1,10 g / cc).

Engineer Cevolini states: “To date there is no material upon the 3D printing market that can compete with Windform® RS: the combination of high resistance and high resilience makes Windform® RS unique in the AM world.”

The high resilience/strength properties allow it to withstand shocks at various ranges of temperature, even sub-zero (it has been successfully tested to – 40 °C, -40 °F).

Windform® RS has been rated HB according to the flammability UL 94 test; moreover, it exhibits waterproof characteristics down to just 1 millimeter part thickness.

“Windform® RS is an astounding advancement in engineered materials, offering a unique opportunity with the durability, strength and flexibility needed for a wide range of additive manufacturing applications.

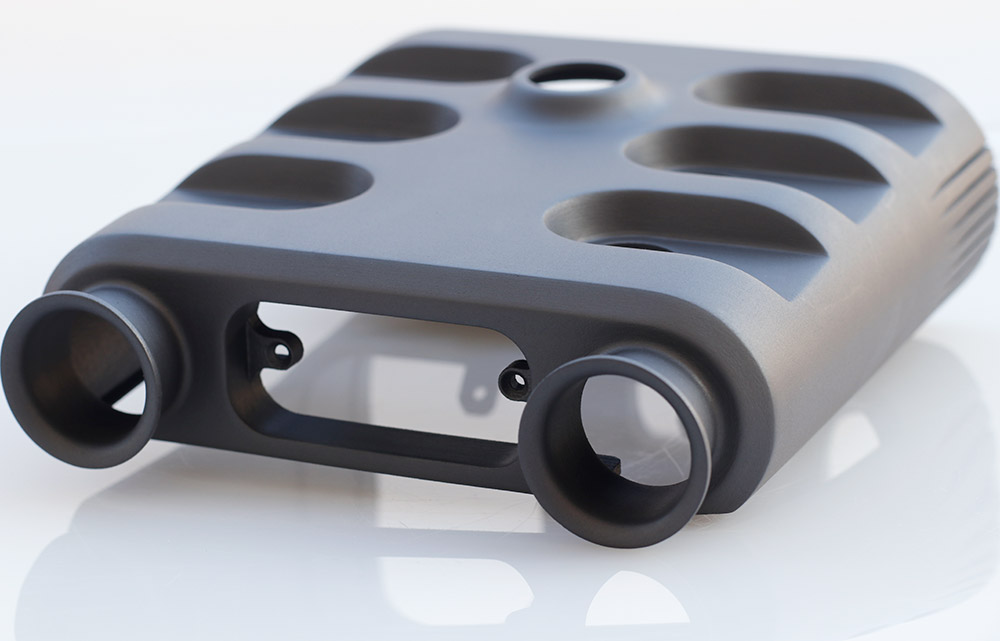

Windform® RS is suited for tough, intricate and complex 3D printed PBF parts, robust functional prototypes and heavy-duty end-use applications withstanding harsh environments.

Windform® RS is ideal for custom production, preseries parts and mission-critical components for the most demanding industry such as Aerospace, Military, Robotics, Motorsports, Automotive and Marine.