Industry

Aerospace

Speed up the design process

Home / Industries / Aerospace

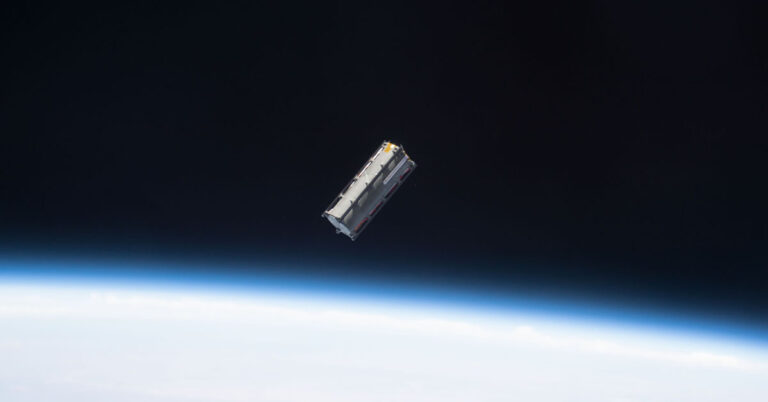

The revolution among the stars

Our Aerospace Specialists will assist your design experts to get the best results from your additive manufacturing concepts, including improvements to reduce mass, weight, costs and lead-times, while enhancing safety-critical space approved components.

Windform range has created a new realm of possibilities for satellite, aerospace and aviation designers to go beyond standardized requirements and limitations.

- less 60% in weight

- strong yet stiff

- space ready. Windform has been validated by NASA, ESA, JAXA and other space agencies internationally

- extreme design with proven structural functionality

- improved miniaturization and co-existence of possibly conflicting items in a very reduced volume such as the PCB’S, cameras for visual observation and radio systems

- reduced complexity: no assembly requirements, one-off component

- reduced costs and lead time

- substantial modifications and improvements in real time

- heavy duty and drilling-proof

- possibility to manufacture enclosure and critically-structural parts and assemblies (moving injection mechanism, doors and others)

- vibration tested to NASA GEVS-7000 specifications, subjected to a near vacuum to simulate the conditions in Earth orbit

- operating temperature range ~ +191,90° ÷ -40°c

- resistant to water entrance already at 1mm thickness

- irradiation damages, aggressive environment, high temperature

- extreme surface finishing for orbital launch

They trust CRP Technology

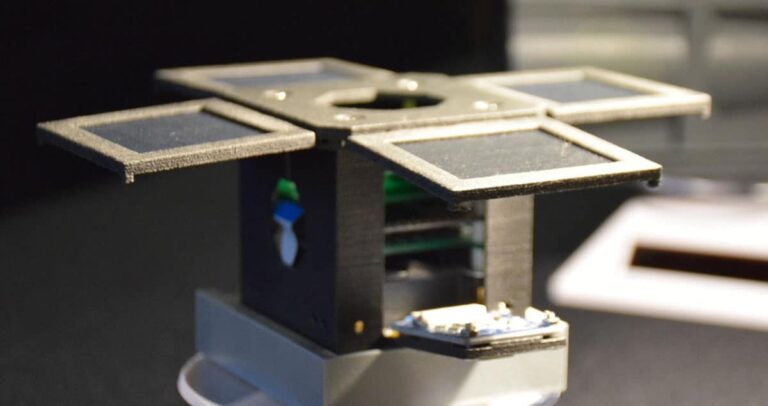

" Thanks to CRP’s laser sintering technology and Windform® XT 2.0 Carbon-reinforced composite material, we obtained very important key advantages such as mass reduction, component integration, outgassing control, thermal expansion, and low surface roughness. We are more than satisfied with selective laser sintering technique Powder Bed Fusion process and consider Windform® XT 2.0 one of the disruptive revolutions in the small satellites arena. We do hope to use additive manufacturing intensively in space application. "

TeamLISA

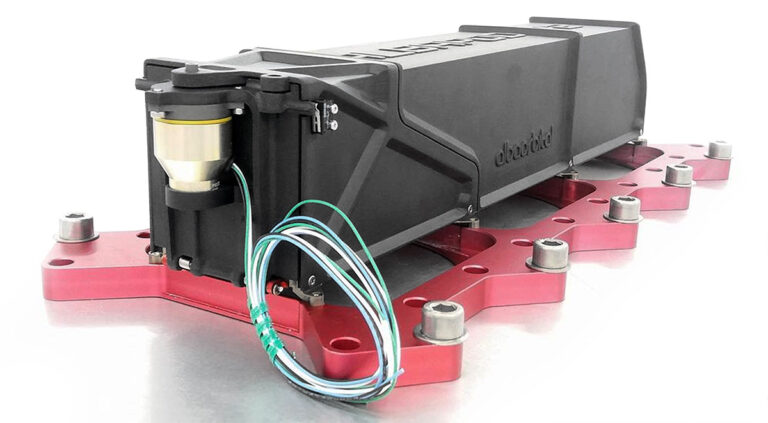

" The most innovative aspect of the project was the sheer number of components we switched over to Windform® XT 2.0, not only was the shell redesigned in the material, but also the moving ejection mechanism and door assembly."

TeamAlba Orbital